Titanium bar, rod specifications

Titanium bar, rod specifications

| Standard | ASTM B348/ASME SB348, ASTMF67, ASTM F136, ISO-5832-2(3), AMS4928, MIL-T-9047G, JIS etc |

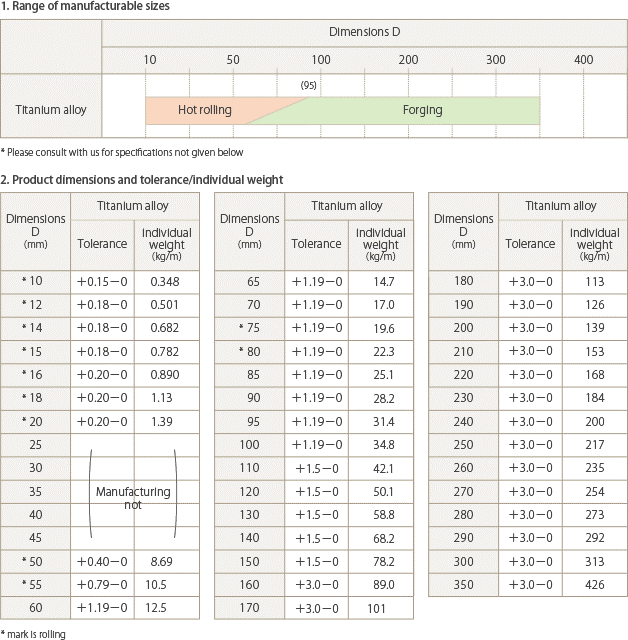

| Grade | ▲ Gr1, Gr2, Gr3, Gr4▲ Gr5 (Ti-6Al-4V)

▲ Gr7 (Ti-0.2Pd) ▲ Gr9 (Ti-3Al-2.5V) ▲ Gr12 (Ti-0.3Mo-0.8Ni) ▲ Gr23 (Ti-6Al-4V ELI) |

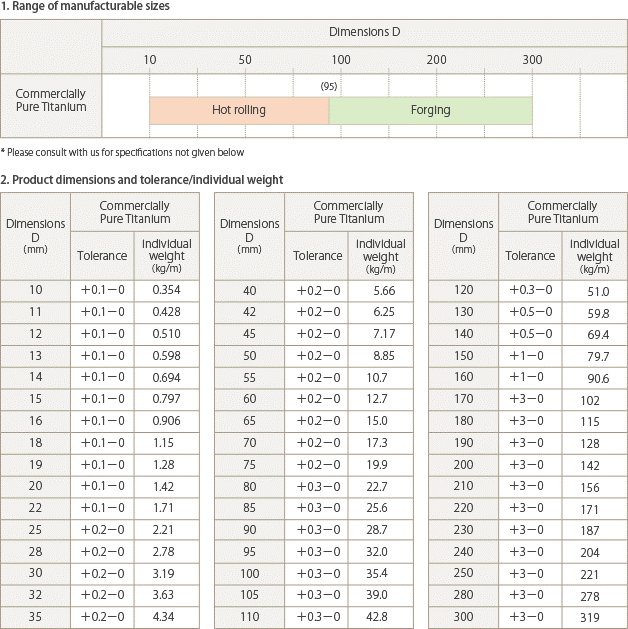

| Titanium Round Bar Size | Diameter: 2~300mm |

| Titanium Square Bar Size | 5*5mm~100*100mm Thickness: 2~300mm |

| Titanium Flat Bar Size | Width: 10~300mm Thickness: 2~300mm |

| Titanium Hex Bar Size | 2~300mm |

| Length | 100~3000mm |

| Technical | Forged, Machining |

| Delivery state | Hot working state(R), Cold working state(Y), Annealing state(M) |

| Surface | Acid surface, Polishing, Sand Blasting Finished, Bright, Polished |

| Shape | Round, Flat, Square, Hexagonal, Rectangle |

| Titanium Rod Form | Round, Square, Hex(A/F), Rectangle, Billet |

| Application | Metallurgy, electronics, medical, chemical, petroleum, pharmaceutical, aerospace, etc. |

Titanium rod is a metal bars crafted from Titanium Ore. It has good performance of wear-resisting and anti-corrosion. It has low density and high strength, making it an essential structural material for industrial production.

The density of titanium metal is 4.51g/CM3, which is higher than aluminum and lower than steel, copper and nickel, but the specific strength is the first metal.

In the air or oxygen-containing media, the surface of titanium generates a dense, strong adhesion, inert oxide film, which protects the titanium substrate from corrosion.

Titanium metal is subject to mechanical vibration, electrical vibration, compared with steel, copper metal, its own vibration decay time is long

Due to the yield limit of titanium and the modulus of elasticity ratio is large, so that the titanium molding rebound ability is large

Not contain harmful metals has good compatibility with your body’s blood and tissues.

| ROD, BAR & FORGINGS | ||

| Sizes: Bar & RodFull Range of sizes in all grades |

GRADE | SPECIFICATIONS |

| 6AL-4V, 6AL-4V ELI | AMS-4928, 4930,4965, 4967, MIL-T-9047, AMS-T-9047, ASTM-F-367 |

|

| 6AL-2SN-4ZR-2MO | AMS04975, MIL-T-9047, AMS-T-9047 | |

| 6AL-6V-25SN | AMS-4978, MIL-T-9047, AMS-T-9047 | |

| 5AL-2.55N | AMS-4926, 4966, MIL-T-9047, AMS-T-9047, B50TF22 | |

| 8AL-1MO-IV | AMS-4972, 4973, MIL-T-9047, AMS-T-9047 | |

| CP-GRADES 1,2,3,4,7 | AMS-4921, MIL-9047, ASTM-B-348, ASTM-F-67 | |

Titanium alloy bars, especially Ti-6AL-4V alloy bars, titanium connecting rods are used in automobile engines, which are not only wear-resistant but also light in weight, reducing the weight of automobiles

Subsequently, titanium was used in titanium spring seats, silencers, and exhaust gas tanks. Of course, titanium rods are used as stirring rods and fasteners in the chemical industry because of their corrosion resistance and wear resistance

In addition, the superior performance of titanium has also attracted the attention of the medical profession, contributing to the development of medicine and human health.

Common titanium and zirconium bar applications include:

Shafts and impellers for mixing equipment

| Grade | Status | Tensile Strength | Yield Strength | Elongation | Area of Reduction | ||

| Ksi | Mpa | Ksi | Mpa | % | |||

| GR1 |

Annealed

|

35 | 20 | 25 | 170 | 24 | 30 |

| GR2 | 50 | 345 | 40 | 275 | 20 | 30 | |

| GR3 | 65 | 450 | 55 | 380 | 18 | 30 | |

| GR4 | 80 | 550 | 70 | 483 | 15 | 25 | |

| TI-6AL-4VELI | 125 | 860 | 115 | 795 | 10 | 25 | |

| Ti6AL7Nb | 130.5 | 900 | 116.8 | 800 | 10 | 25 | |

| Ti13Nb13Zr | ageing125Solid 800

Not annealed 800

|

860

550

550 |

105500

500 |

725345

345 |

815

8 |

1530

15 |

|

| N | C | H | Fe | O | Al | V | Pa | Mo | Ni | Ti | |

| Gr. 1 | 0.03 | 0.08 | 0.015 | 0.2 | 0.18 | / | / | / | / | / | Remaining |

| Gr. 2 | 0.03 | 0.08 | 0.015 | 0.3 | 0.25 | / | / | / | / | / | Remaining |

| Gr. 3 | 0.05 | 0.08 | 0.015 | 0.3 | 0.35 | / | / | / | / | / | Remaining |

| Gr. 4 | 0.05 | 0.08 | 0.015 | 0.5 | 0.4 | / | / | / | / | / | Remaining |

| Gr. 5 | 0.05 | 0.08 | 0.015 | 0.4 | 0.2 | 5.5~6.75 | 3.5~4.5 | / | / | / | Remaining |

| Gr. 7 | 0.03 | 0.08 | 0.015 | 0.3 | 0.25 | / | / | 0.12~0.25 | / | / | Remaining |

| Gr. 9 | 0.03 | 0.08 | 0.015 | 0.25 | 0.15 | 2.5~3.5 | 2.0~3.0 | / | / | / | Remaining |

| Gr.12 | 0.03 | 0.08 | 0.015 | 0.3 | 0.25 | / | / | / | 0.2~0.4 | 0.6~0.9 | Remaining |

Grand Titanium offers a complete range of services, starting from basic cutting and processing to more complex and bespoke solutions. This range includes:

Grand Titanium is a global professional titanium bar, rod manufacturers, and supplier in China, all our products are manufactured in accordance with ASTM, AMS, and ISO international standards. and we make it easy for you to find the product you need with quick shipments!

Located in Changzhou,Jiangsu, Grand has been supplying metallic products for 17 years. Material ration in line with international standards.

Complete supporting equipment, the introduction of the industry’s top roller drawing equipment, inspection and testing equipment to ensure production output and quality stability.

Source factory production, direct sales in reasonable price

Copper bar is a kind of non-ferrous metal processing bar, which has better processing performance and high conductivity. It is mainly divided into brass rod (copper zinc alloy, cheaper), purple copper rod (higher copper content).

Brass rod is a rod shaped object made of copper and zinc alloy, named for its yellow color. The melting point of brass, which contains 56% to 68% copper, is 934 to 967 degrees. Brass has good mechanical properties and wear resistance, and can be used to manufacture precision instruments, ship parts, gun casings and so on. Used in air conditioning pipe, refrigerator pipe, oil pipe, water supply pipe and all kinds of mechanical materials, automotive synchronizer gear ring, Marine pump, valve, structural parts, friction accessories, etc.

Purple copper rod is named for its purple red color. It has good electric conductivity, heat conduction, corrosion resistance and processing properties. It can be welded and brazed. Characteristics: high purity, fine structure, low oxygen content. No porosity, trachoma, loose, excellent electrical conductivity, high precision of electroetching mold surface, after heat treatment process, no direction of the electrode, suitable for fine play, fine play, with good thermoelectric channel, processability, ductility, corrosion resistance and weather resistance.

Brass coil has excellent plasticity (best in brass) and high strength, good machinability, easy to weld, very stable to general corrosion, but prone to corrosion cracking; brass coil is copper and the alloy of zinc is named for its yellow color.

The mechanical properties and wear resistance of the brass coil are very good, and can be used to manufacture precision instruments, ship parts, shells of guns, etc. Brass knocks up and sounds good, so instruments such as cymbals, cymbals, bells, and numbers are made of brass. According to the chemical composition, brass is divided into ordinary copper and special brass.

It may seem that a copper coil is a simple piece of coiled wire that can be wound and put to use. As with any form of industrial product, copper coils have to be precisely engineered to fit an application. The winding process has to be completed with precision to ensure the proper distance between the wires and the diameter of the opening.

Each product that uses copper coils requires that a certain number of turns be made to provide the correct amount of resistance. Inaccurate calculations can lead to inefficiency and possible failure of the coil or device. For this reason, the engineers at Metal Associates guarantee that they have closely examined the specification of an application such that the diameter, spacing, wire thickness, and number of turns exactly matches the design of the product where the copper coil will be used.

Copper is a reddish brown metallic element with outstanding characteristics such as good ductility, ductility, heat and conductivity

Pure copper is a very soft and ductile metal To achieve the required performance, we can alloy with other metals Brass and bronze are widely used copper alloys

Copper foil is made of copper or copper alloy by hot rolling and cold rolling The thickness of copper foil ranges from 0.03mm to 0.2mm, and the width and length can be customized according to customer requirements

Aluminium foil is aluminium prepared in thin metal leaves with a thickness of less than 0.2mm (7.9 mils); thinner gauges down to 4 micrometers are also commonly used. Standard household foil is typically 0.016 mm (0.63 mils) thick, and heavy-duty household foil is typically 0.024 mm (0.94 mils). And the air conditioner foil can be thinner than 0.0047mm, and some food foil thinner than 0.002mm. The foil is pliable and can be readily bent or wrapped around objects. Thin foils are fragile and are sometimes laminated with other materials such as plastics or paper to make them stronger and more useful. It’s used industrially for a variety of purposes, including packing, insulation and transportation. At home, people use aluminum foil for food storage, to cover baking surfaces and to wrap foods, such as meats, to prevent them from losing moisture while cooking.

Titanium plate has high corrosion resistance and specific strength, and is widely used in electric power, chemical industry, aviation parts, building materials, sports equipment, medical and other fields and is still expanding. From the point of view of use and manufacturing technology, titanium plate has low price, high performance, multiple functions, and easy production.

If any questions,please feel free to contact sales@grandsteeltube.com

Stainless Steel Strip is an austenitic chromium-nickel-manganese stainless steel that offers electromagnetic properties like electrical resistivity, magnetic permeability & electrical conductivity and Young’s Modulus of Elasticity. We offer these stainless steel strips in various material grades such as Stainless Steel 304 Strips, Stainless Steel 310 Strips, Stainless Steel 316 Strips, Stainless Steel 904 Strips and many more.

Hot Rolled Stainless Steel Strips are produced from hot rolling billets or slabs and then use a cold rolling process. These processes improve strips mechanical properties such as stiffness coefficient and flexibility. Cold Rolled Stainless Steel Strips are obtained from annealed and pickled by cold rolling on polished rolls. As per the required thickness, cold rolling requires a number of passes through mill to effect reduction.

We supply SS Strips in various industries including food industries, chemical, electrical, generator, shaft, cement & gas industries. The offered these Stainless Steel Strips in standards as well as customized dimensions as per the client’s requirement.

Aluminum sheet & foil in the form of rolls with a thickness > 0.2mm, a width 20mm to 100mm is generally called aluminium strip. The common name for aluminium strip that is produced in small strip widths is usually split strip. Aluminium sheets are cut into a required by slitting tooling, the raw material of aluminum strip is pure aluminium or aluminum alloy hot rolled cast-rolling aluminum coil and hot-rolled coil. Through a cold-rolled machine to form different thickness and width of the rolling sheet and aluminum coil, and then the vertical cutting and slitting machine for different width of the strip. And the thickness<0.2mm, we call it aluminum foil strip or aluminum foil coil.

Aluminium coil is a rolled product, produced in a coiled form of a continuous strip, and has an inner diameter and outer diameter. ID from50mm to 1000mm. Aluminium alloy grade including 1xxx, 2xxx, 3xxx, 4xxx, 5xxx, 6xxx, 7xxx, 8xxx. But the most common is 1050, 3003, 6061 and 5251 aluminum coil. Thickness from 0.045-80mm, width from 60-2650mm. Common widths of aluminum coil is 800mm,1000mm, 1250mm,1450mm and 1500mm.

Multiple industries rely on aluminium coils for a variety of applications, such as automotive, construction, heat transfer, pharmaceutical, electrical, and food industry. Compared to other materials, aluminum is a far superior material in many instances. Aluminum coil can be supplied with standard mill finish, or it can be brushed, checkered, color coated, satin-finished and anodized. Aluminium sheet or aluminium foil can be cut into coils as per client’s requirements.

Titanium strip is produced from the titanium sheet. Usually cold-rolled the titanium sheet by a small mill with annealing for several times, then slitting shear to titanium strips according to customer requirements. The advanced equipment, rolling process, process control, annealing temperature and return time control ensured its smoothness and finish, effectively improved the quality of our products.