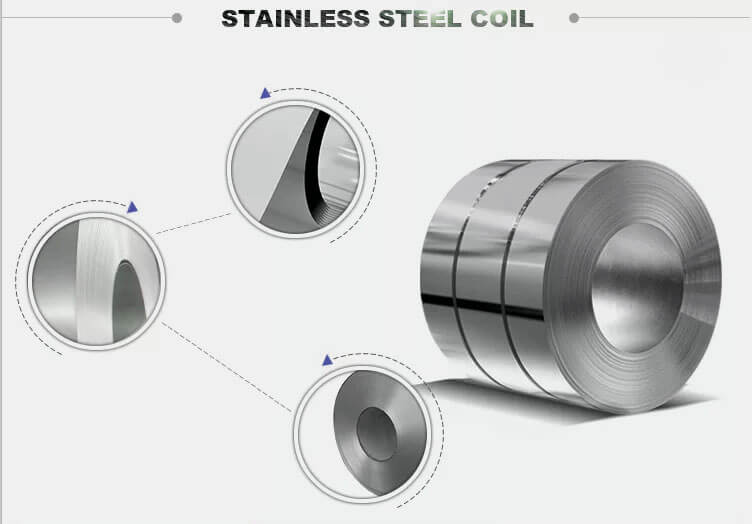

Stainless Steel Coil

Stainless steel coil can be divided into cold rolled stainless steel coil and hot rolled stainless steel coil according to different production processes.

According to the materials, they can be divided into austenite, martensite, ferrite and duplex.

Common use stainless steel coils grades are often represented by digital symbols.

There are 200 series, 300 series, 400 series and duplex series.

304, 304L, 316 and 316L stainless steel coils are the most popular and economical grades of stainless steels.

Stainless steel 304/304L coils and stainless steel 316/316L coils, along with duplex stainless steel coils offer good corrosion resistance to many chemical environments as well as marine and industrial exposures.

- Description

- Stainless Steel Coils Mechanical Properties

- Inquiry

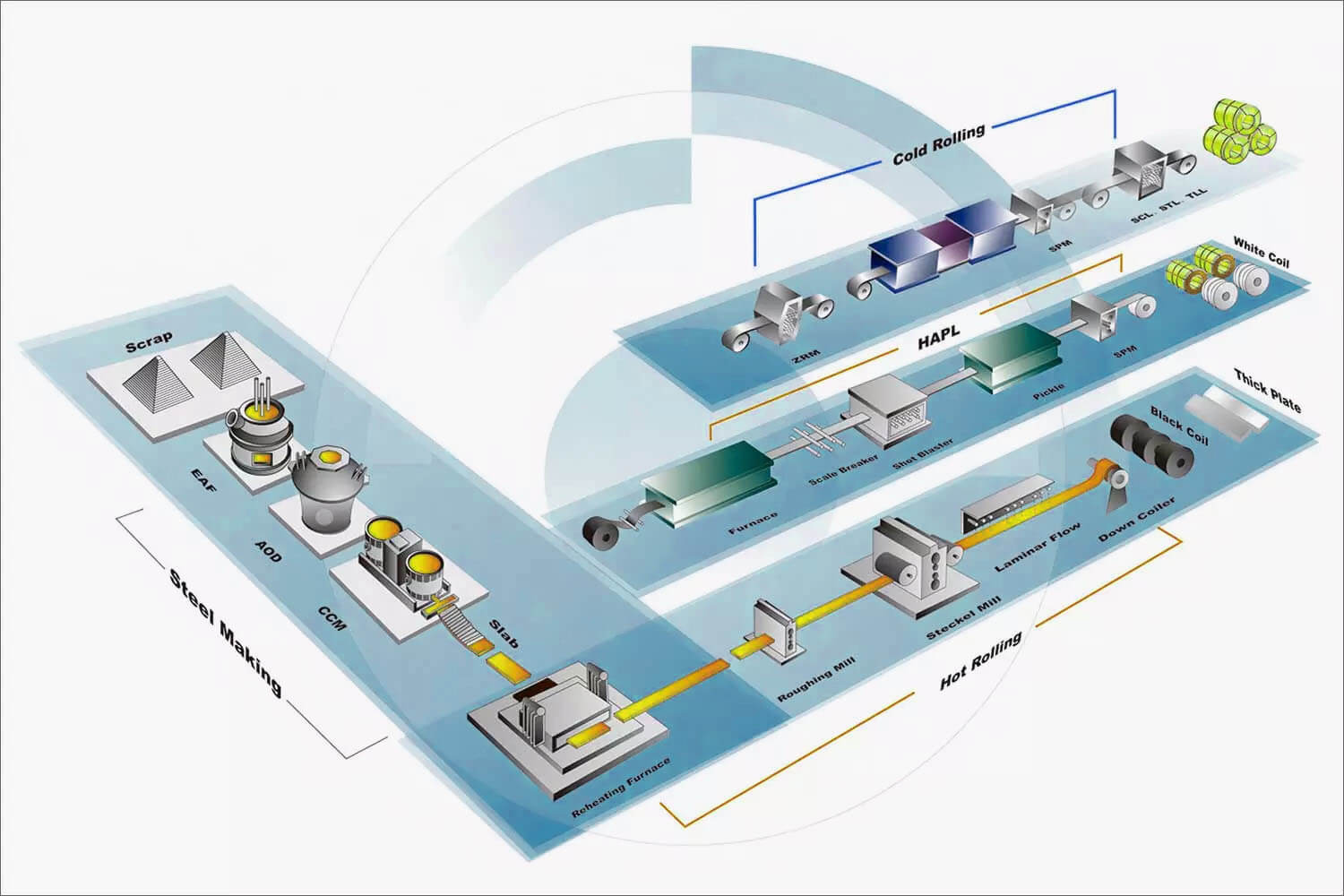

How Stainless Steel Coils Are Made?

Stainless steel coils are the most widely used type of metal coil in the market. They are mainly used for making pipes, tubes and sheets. These stainless steel coils are manufactured using different types of raw materials and advanced technology.

Stainless steel coils are made using several processes like hot rolling, cold rolling and extrusion. The process of making these coils depends on their thickness, diameter, length and width. The most common process used to manufacture stainless steel coils is hot rolling process. It involves melting the raw material at high temperature and then shaping it into desired forms by rolling them through a series of rollers that have varying degrees of hardness. This process results in producing large sized products with a uniform thickness, size and shape.

The second commonly used process is cold rolling process which is carried out under controlled conditions so as to maintain product quality during production stages. In this process, the material undergoes three processes namely roughing pass (first pass), semi-finishing pass (second pass) and finishing pass (third pass). This method produces products with high dimensional accuracy and good surface finish with low yield loss due to less friction during rolling process.

What Are The Advantages of Using Stainless Steel Coils?

Stainless steel coils are an excellent choice for a variety of applications, including heating and cooling systems, food processing facilities and even your home.

They are highly durable and can withstand high temperatures. In addition, they offer many advantages over other types of metal coils:

Prolonged Lifespan

Stainless steel coils have a much longer lifespan than copper or aluminum. This means that you will get more use out of these coils before they need to be replaced. They also require less maintenance so you won’t have to worry about repairing them as often as other types of coils.

High-Temperature Resistance

Stainless steel coils can withstand temperatures up to 2,000 degrees Fahrenheit without melting or warping. This makes them ideal for industrial processes that involve extreme heat such as chemical manufacturing and oil refineries. They can also be used in residential applications such as cooking stoves and fireplaces where there is a risk of fire starting due to exposed flames from burning wood or coal fires.

Heat Transfer Efficiency

Stainless steel has excellent thermal conductivity properties that allow it to transfer heat quickly throughout its entire length — unlike other metals that may only conduct heat through their outer layers while their inner layers remain cool.

What Are The Grades of Stainless Steel Coils?

| Austenitic Stainless Steel | 301, 303, 304, 304L, 309S, 310S, 316/316L, 321, 347, 904L, etc | |||

| Martensitic Stainless Steel | 410, 414, 416, 416, 420, 431, 440A, 440B, 440C, etc | |||

| Duplex Stainless Steel | S31803, S32101, S32205, S32304, S32750, etc | |||

| Ferritic Stainless Steel | 429, 430, 433, 434, 435, 436, 439, etc | |||

Stainless steel coil is an alloy steel with smooth surface, high weldability, corrosion resistance, polishability, heat resistance, corrosion resistance and other characteristics.

It is widely used in various industries and is an important material in modern industry.

Stainless steel coil is divided into austenitic stainless steel, ferritic stainless steel, martensitic stainless steel, and duplex stainless steel according to the structure state.

Austenitic Stainless Steel Coils:

stainless steel with an austenitic structure at room temperature. Steel contains Cr≈18%, Ni≈8%-25% and C≈0.1%. Steel has high toughness and plasticity, but low strength.

Martensitic Stainless Steel Coils:

A steel whose mechanical properties can be adjusted by heat treatment. It has different strength and toughness at different tempering temperatures.

Duplex Stainless Steel Coils:

Austenitic and ferrite each account for about half of the structure. When the C content is low, the Cr content is 18% to 28%, and the Ni content is 3% to 10%. Some steels also contain alloying elements such as Mo, Cu, Si, Nb, Ti, and N. This type of steel has the characteristics of austenitic and ferritic stainless steel

Ferritic Stainless Steel Coils:

It contains 15% to 30% chromium and has a body-centered cubic crystal structure. This type of steel generally does not contain nickel, and sometimes contains a small amount of Mo, Ti, Nb and other elements. This type of steel has the characteristics of large thermal conductivity, small expansion coefficient, good oxidation resistance, and excellent stress corrosion resistance.

What Are The Edges Options of Stainless Steel Coils?

Mill edge is a non-trimmed edge appearance after hot or cold rolling and annealing/pickling process. It usually leaved an irregular pinhole line on the edge side around 10mm to 15mm.

Slit/slitting edge means we will trim irregular pinhole line on our slitting machine.

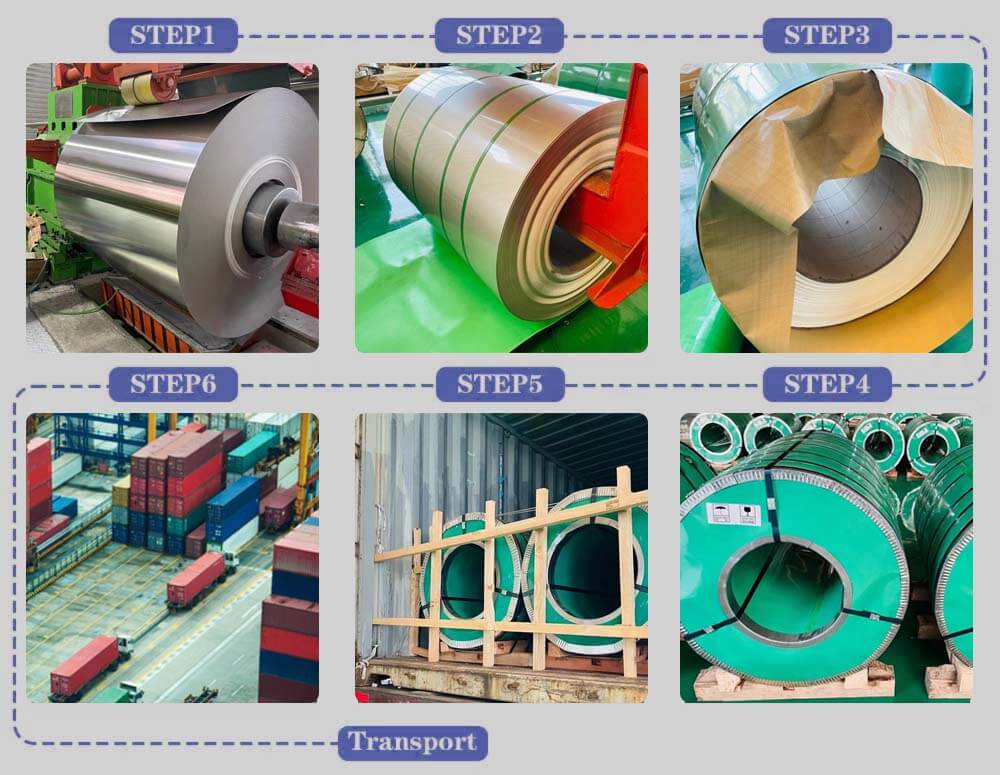

What Is The Packaging Standard of Stainless Steel Coils?

- Standard export sea packaging:

Waterproof Paper Winding+PVC Film+Strap Banding+Wooden Pallet or Wooden Case; - Customized packaging as your request (Logo or other contents accepted to be printed on the packaging);

- Other special packaging will be designed as customer’s request;

Eye to wall and eye to sky are both available; - By International Express: DHL/UPS/FEDEX/EMS and our own express line;

- By air or By sea;

- Shipping port: Shanghai, Ningbo or as your request.

What Is The HS Code of Stainless Steel Coils?

7219110000 – hot rolled stainless steel coil with thickness > 10mm;

7219120000 – 4.75mm ≤ 10mm thick hot rolled stainless steel coil;

7219131200 – hot rolled stainless steel coil with 3mm ≤ thickness < 4.75mm without pickling;

7219131900 – other hot rolled stainless steel coils with 3mm ≤ thickness < 4.75mm without pickling.

What Is The Mill Origin of Your Stainless Steel Coils?

Our professional management team only purchase the high quality stainless steel mother coils and make sure all the material we use is up to our factory standards.

Our prime coils mill origins are really famous such as TISCO, BAOWU, JISCO, POSCO, OUTOKUMPU.

Only in this way can we supply high quality cold rolled and hot rolled stainless steel coils for global users.

Stainless Steel Coils Mechanical Properties

| Grade | Standard | Yield Strength Rp0.2 (N/mm²) |

Tensile Strength Rm (N/mm²) |

Elongation % | Hardness (HV) |

Hardness (HRB) |

|---|---|---|---|---|---|---|

| 201 | ASTM A240 | ≥ 275 | ≥ 520 | ≥ 35 | ≤ 260 | ≤ 101 |

| 202 | ASTM A240 | ≥ 275 | ≥ 520 | ≥ 40 | ≤ 218 | ≤ 95 |

| 301 | ASTM A240 | ≥ 205 | ≥ 520 | ≥ 40 | ≤ 200 | ≤ 90 |

| 304 | ASTM A240 | ≥ 205 | ≥ 515 | ≥ 40 | ≤ 210 | ≤ 92 |

| 304L | ASTM A240 | ≥ 205 | ≥ 520 | ≥ 40 | ≤ 200 | ≤ 90 |

| 316L | ASTM A240 | ≥ 177 | ≥ 480 | ≥ 40 | ≤ 200 | ≤ 90 |

| 316Ti | ASTM A240 | ≥ 205 | ≥ 520 | ≥ 40 | ≤ 200 | ≤ 90 |

| 317L | ASTM A240 | ≥ 205 | ≥ 515 | ≥ 40 | ≤ 218 | ≤ 95 |

| 309S | ASTM A240 | ≥ 205 | ≥ 515 | ≥ 40 | ≤ 218 | ≤ 95 |

| 310S | ASTM A240 | ≥ 205 | ≥ 520 | ≥ 40 | ≤ 200 | ≤ 90 |

| 321 | ASTM A240 | ≥ 205 | ≥ 520 | ≥ 40 | ≤ 200 | ≤ 90 |

| 347 | ASTM A240 | ≥ 205 | ≥ 520 | ≥ 35 | ≤ 200 | ≤ 90 |

| 410S | ASTM A240 | ≥ 205 | ≥ 440 | ≥ 20 | ≤ 210 | ≤ 92 |

| 420J2 | ASTM A240 | ≥ 225 | ≥ 540 | ≥ 18 | ≤ 180 | ≤ 80 |

| 430 | ASTM A240 | ≥ 206 | ≥ 450 | ≥ 22 | ≤ 200 | ≤ 88 |

| 2205 | ASTM A240 | ≥ 450 | ≥ 620 | ≥ 25 | ≤ 293 | ≤ 30 |

| 2507 | ASTM A240 | ≥ 450 | ≥ 620 | ≥ 25 | ≤ 290 | ≤ 30 |

| 253 MA® | ASTM | ≥ 310 | ≥ 600 | ≥ 40 | ≤ 217 | ≤ 95 |

| 254 SMO® | ASTM | ≥ 300 | ≥ 650 | ≥ 35 | ≤ 223 | ≤ 96 |

| 654 SMO® | ASTM | ≥ 430 | ≥ 750 | ≥ 40 | ≤ 250 | ≤ 100 |

| 904L | ASTM | ≥ 216 | ≥ 490 | ≥ 35 | - | ≤ 90 |

| UNS N08926 | ASTM | ≥ 295 | ≥ 650 | ≥ 35 | - | ≤ 100 |

| UNS S17400 | ASTM | ≥ 725 | ≥ 930 | ≥ 10 | - | - |

Related Products

-

Read MoreQuick View

Read MoreQuick ViewTitanium Foil

Titanium foil is a titanium plate, strip, roll or sheet with a thickness of less than or equal to 0.2mm. The maximum width of rolled titanium foil is about 600mm.

The width of the titanium foil is cut according to the requirements of the user.But the wider the manufacturing, the higher the productivity.

Titanium foil is mainly used in aerospace, navigation, nuclear power, electronics, chemical industry, petroleum, precision manufacturing, medical pharmaceutical and other aspects. -

Read MoreQuick View

Read MoreQuick ViewTitanium Sheet

Titanium plate has high corrosion resistance and specific strength, and is widely used in electric power, chemical industry, aviation parts, building materials, sports equipment, medical and other fields and is still expanding. From the point of view of use and manufacturing technology, titanium plate has low price, high performance, multiple functions, and easy production.

If any questions,please feel free to contact sales@grandsteeltube.com

-

Read MoreQuick View

Read MoreQuick ViewCopper Foil

Copper is a reddish brown metallic element with outstanding characteristics such as good ductility, ductility, heat and conductivity

Pure copper is a very soft and ductile metal To achieve the required performance, we can alloy with other metals Brass and bronze are widely used copper alloys

Copper foil is made of copper or copper alloy by hot rolling and cold rolling The thickness of copper foil ranges from 0.03mm to 0.2mm, and the width and length can be customized according to customer requirements

-

Read MoreQuick View

Read MoreQuick ViewCopper Rod

Copper bar is a kind of non-ferrous metal processing bar, which has better processing performance and high conductivity. It is mainly divided into brass rod (copper zinc alloy, cheaper), purple copper rod (higher copper content).

Brass rod is a rod shaped object made of copper and zinc alloy, named for its yellow color. The melting point of brass, which contains 56% to 68% copper, is 934 to 967 degrees. Brass has good mechanical properties and wear resistance, and can be used to manufacture precision instruments, ship parts, gun casings and so on. Used in air conditioning pipe, refrigerator pipe, oil pipe, water supply pipe and all kinds of mechanical materials, automotive synchronizer gear ring, Marine pump, valve, structural parts, friction accessories, etc.

Purple copper rod is named for its purple red color. It has good electric conductivity, heat conduction, corrosion resistance and processing properties. It can be welded and brazed. Characteristics: high purity, fine structure, low oxygen content. No porosity, trachoma, loose, excellent electrical conductivity, high precision of electroetching mold surface, after heat treatment process, no direction of the electrode, suitable for fine play, fine play, with good thermoelectric channel, processability, ductility, corrosion resistance and weather resistance.

-

Read MoreQuick View

Read MoreQuick ViewAluminium Coil

Aluminium coil is a rolled product, produced in a coiled form of a continuous strip, and has an inner diameter and outer diameter. ID from50mm to 1000mm. Aluminium alloy grade including 1xxx, 2xxx, 3xxx, 4xxx, 5xxx, 6xxx, 7xxx, 8xxx. But the most common is 1050, 3003, 6061 and 5251 aluminum coil. Thickness from 0.045-80mm, width from 60-2650mm. Common widths of aluminum coil is 800mm,1000mm, 1250mm,1450mm and 1500mm.

Multiple industries rely on aluminium coils for a variety of applications, such as automotive, construction, heat transfer, pharmaceutical, electrical, and food industry. Compared to other materials, aluminum is a far superior material in many instances. Aluminum coil can be supplied with standard mill finish, or it can be brushed, checkered, color coated, satin-finished and anodized. Aluminium sheet or aluminium foil can be cut into coils as per client’s requirements.

-

Read MoreQuick View

Read MoreQuick ViewCopper Coils

It may seem that a copper coil is a simple piece of coiled wire that can be wound and put to use. As with any form of industrial product, copper coils have to be precisely engineered to fit an application. The winding process has to be completed with precision to ensure the proper distance between the wires and the diameter of the opening.

Each product that uses copper coils requires that a certain number of turns be made to provide the correct amount of resistance. Inaccurate calculations can lead to inefficiency and possible failure of the coil or device. For this reason, the engineers at Metal Associates guarantee that they have closely examined the specification of an application such that the diameter, spacing, wire thickness, and number of turns exactly matches the design of the product where the copper coil will be used.

-

Read MoreQuick View

Read MoreQuick ViewStainless Bar

A stainless steel bar stock is often used for production line machinery or in other industrial settings where durability is required. Stainless steel round bar types can be found in many different shapes such as hexagon, square, or round bars. Stainless bar stock is a material that is non-corrosive, corrosion resistant, and durable. It can be used in a variety of industries such as automotive, aerospace, construction, and manufacturing.

Stainless steel bar stock is the highest quality type of stainless steel in the industry. They are made with high-quality materials that make them resistant to corrosion and other environmental conditions. The stainless bar stock also has greater tensile strength than other types of stainless steel.

Stainless steel round rod products or round bars are commonly used for manufacturing products like car rims, motorcycle rims, bicycle rims, and more. These types of bars are typically made by rolling up sheets of stainless steel into long tubes before welding them together at the ends to create round rods or round bars that can be cut into smaller pieces

-

Read MoreQuick View

Read MoreQuick ViewAluminium Strip

Aluminum sheet & foil in the form of rolls with a thickness > 0.2mm, a width 20mm to 100mm is generally called aluminium strip. The common name for aluminium strip that is produced in small strip widths is usually split strip. Aluminium sheets are cut into a required by slitting tooling, the raw material of aluminum strip is pure aluminium or aluminum alloy hot rolled cast-rolling aluminum coil and hot-rolled coil. Through a cold-rolled machine to form different thickness and width of the rolling sheet and aluminum coil, and then the vertical cutting and slitting machine for different width of the strip. And the thickness<0.2mm, we call it aluminum foil strip or aluminum foil coil.

-

Read MoreQuick View

Read MoreQuick ViewCopper Strips

Copper strips have high electrical and thermal conductivity, that’s why copper strips are the best for transformer winding.

What’s more, copper strips transfer heat more effectively than other metals strips.

Copper strips are more malleable and have high tensile strength. Corrosion resistance, high degree stability, and heat dissipation of copper strips are superior to other metals.

Copper strips are mostly used in the electrical and electronics sectors because copper is non-magnetic and non-sparking. Copper strips are mostly used in heat exchangers, transformers winding, condensers, and lightning conductors.

Copper strip thickness range from 0.03mm to 3.0mm. Copper strips can be manufactured in different widths and thicknesses per the customer’s requirement.

If any questions, please feel free to contact sales@grandsteeltube.com

-

Read MoreQuick View

Read MoreQuick ViewStainless Steel Foil

Stainless steel foils are thin strips of stainless steel that are less than 0.2 mm in thickness and less than 300 mm in width.

Stainless steel foils offer a variety of advantages, including chemical stability, high strength-to-weight ratio, electrical insulation and corrosion resistance.

Stainless steel foil is used in the production of heat exchangers, capacitors and fuel cells; as well as in medical equipment and food processing machinery.

Stainless steel foils are a versatile material with many advantages. Its high corrosion resistance, good thermal and electrical conductivities and its ductility makes it an excellent choice for a wide range of applications.

Stainless steel foil is available in several different grades. These include austenitic series, ferritic series, martensitic series, duplex and super duplex series. Each grade has different alloying elements that contribute to the properties of the foil.

The most common grades of stainless steel foils are 304 and 316. These grades are supplied in thicknesses ranging from 0.009mm to 0.3mm. Other grades of stainless steel foil are also available upon request including 409, 430 and duplex 2205.

- DIN2391 Precision Steel Tube

- EN10305-1/4 Precision Steel Tube

- EN10305-2/3/5/6 Precision Tubes

- SAE Series Precision Tubes

- ISO8535-1 Fuel Injection Tube

- Single/Doulbe Wall Bundy Tube

- Boiler & Pressure Steel Tubes

- Seamless Honed/SRB Steel Tube

- Stainless Capillary Steel Tubes

- Seamless Stainless Tubes & Pipes

- Welded Stainless Tubes & Pipes

- Injection & Control Line Tubes

- Nickel Alloy Tubes & Pipes

- Non-ferrous Capillary Tubes

- Aluminium Tubes & Pipes

- Brass Tubes & Pipes

- Copper Tubes & Pipes

- Titanium Tubes & Pipes

- Extruded/Welded Fin Tube

- Non-Ferrous Precision Tube

- Special Shaped Steel Tubes

- Metallic Coil/Foil/Sheet/Strip