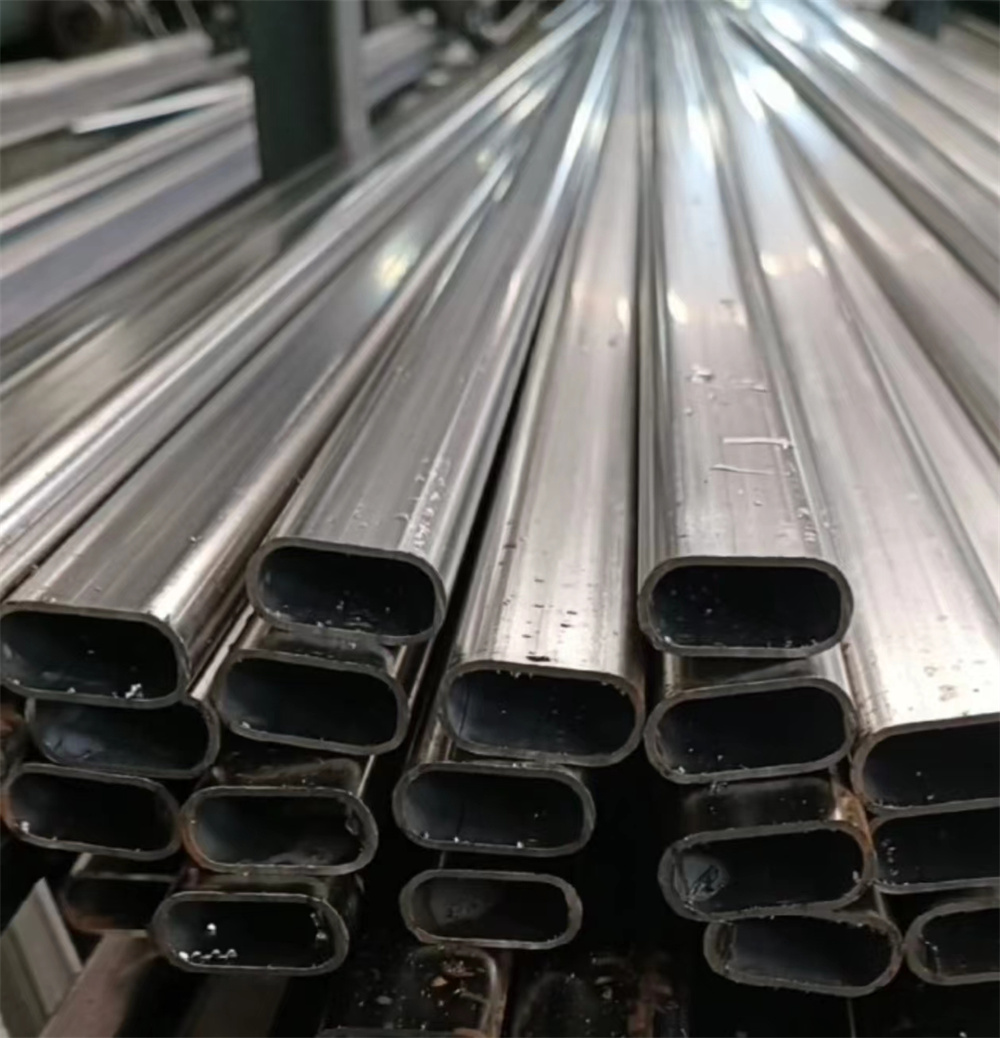

Stainless Oval Tube

Because of their propensity to have extremely high ductility, stainless steel is favoured. Any oval stainless steel tubing’s ductility depends on its microstructure, which is a product of the metal’s alloying composition. Consider an alloy grade like 316 Stainless Steel Oval Tube as an example. The metal’s microstructure contains an austenite crystal. Nickel is a component of austenite’s alloy, which contributes to its formation and stability.

Austenite has a face centre cubic microstructure, also known as an FCC, which makes the alloy of Flat Oval Stainless Steel Tube ductile due to the tightly packed atoms. Due to their ductility, austenitic stainless steels may be formed into a variety of shapes, from simple square, rectangular, and round shapes to more intricate ones like the Flat Sided Oval Stainless Steel Tube. In addition to being produced in a variety of shapes, stainless steel oval tubes can have variable diameters, wall thicknesses, and circumferences.

The use of an oval tube has a number of advantages for users. For instance, stainless steel elliptical oval tubeshave a stronger construction and, despite being ductile, are more difficult to distort. Additionally, because to its extremely compact design, the majority of Oval Stainless Steel Tube Suppliers advise using these tubes in applications where there are issues with available space or where compact components are required.

- Keterangan

- Siasatan

|

Produk

|

Wholesales ASTM A554 Stainless Steel Tube

|

|

Standard

|

ASTM A554, EN10296-2

|

|

Bahan

|

304, 304L, 316, 316L, 201, 202, 409L, 410, 430

|

|

Outside Diameter

|

round: 6.0 – 273mm or customized

|

|

square: 8×8 – 100×100mm or customized

|

|

|

rectangular: 20×10 – 120×60mm or customized

|

|

|

oval: 30×15, 80×40 mm or customized

|

|

|

O.D. Tolerance

|

According to ASTM A554 standard

|

|

Ketebalan / Tolerance

|

0.6-3Mm, +/-10%

|

|

Panjang / Tolerance

|

5.8meters or 6meters or customised,

|

|

Process Method

|

Code drawn, annealed with nitrogen protection, ultrasonic, automatic shape, polished

|

|

Finishing

|

Satin / Sanded / Brushed / Hairline HL: 180 grit, 240 grit, 320 grit

|

|

Bright: 400 grit, 600 grit, Mirror: 800 grit / 8K

|

|

|

Tin Titanlum Colour / Wooden Grain Coating

|

|

|

Application

|

Handrail systems, furniture, display shelf, sanitary wares, machinery equipment, automobile

|

|

Packaging

|

Each Tube packed by plastic bag individully then bundle or customized

|

316 1.4401 / X5CrNiMo17-12-2 06Cr17Ni12Mo2 316S16 Z6CND17.12

316L 1.4404 / X2CrNiMo17-12-2 022Cr17Ni12Mo2 316S12 Z2CND17.12

201 1.4372 / X12CrMnNiN17-7-5 12Cr17Mn6Ni5N — X12CrMnNIN17.7.5

202 1.4373 / X12CrMnNiN18-9-5 12Cr18Mn9Ni5N — X12CRMnNIN18.9.5

310 1.4821 / X15CrNi25-21 20Cr25Ni20 — —

310S 1.4845 / X12CrNi23-12 06Cr25Ni20 310S24 Z8CN25.20

321 1.4541 / X6CrNiTi18-10 06Cr18Ni11Ti 321S12 Z6CNT18.10

409 X6CrTi12 06Cr11Ti — —

409L 1.4512 / X2CrTi12 022Cr11Ti — —

410 1.4006 / X12Cr13 12Cr13 410S21 Z12Cr13

410S X6Cr13 06Cr13 — —

430 1.4016 / X6Cr17 10Cr17 430S15 X6Cr17

439 1.4509 / X2CrTiNb18 022Cr18NbTi — —

904L 1.4539 / X1NiCrMoCu25-20-5 015Cr21Ni26SiMo5Cu2 — —

201(1% Nikel) ≤0.15 ≤1.00 8.5-10.0 ≤0.06 ≤0.03 14-16 ≥0.8 N≤0.25

202 ≤0.15 ≤1.00 7.5-10.0 ≤0.06 ≤0.03 17-19 4-6 N≤0.25

304 ≤0.08 ≤1.00 ≤2.0 ≤0.045 ≤0.03 18-20 8-11

304L ≤0.03 ≤1.00 ≤2.0 ≤0.045 ≤0.03 18-20 8-12

316 ≤0.08 ≤1.00 ≤2.0 ≤0.045 ≤0.03 16-18 10-14 2.0-3.0

316L ≤0.03 ≤1.00 ≤2.0 ≤0.045 ≤0.03 16-18 10-14 2.0-3.0

430 ≤0.12 ≤1.00 ≤1.0 ≤0.04 ≤0.03 16-18 ≤0.6

310 ≤0.15 ≤1.00 ≤2.0 ≤0.20 ≥0.15 17-19 8-10

310S ≤0.08 ≤1.50 ≤2.0 ≤0.035 ≤0.03 24-26 19-22

321 ≤0.08 ≤1.00 ≤2.0 ≤0.045 ≤0.03 17-19 9-12 Ti≥5xC

409 ≤0.08 ≤1.00 ≤1.0 ≤0.04 ≤0.03 10.5-11.75 ≤0.5 Ti6xC%≤0.7

410 ≤0.15 ≤1.00 ≤1.0 ≤0.035 ≤0.03 11.5-13.5

410S ≤0.08 ≤1.00 ≤1.0 ≤0.04 ≤0.03 11.5-13.5 ≤0.6

439 ≤0.03 ≤1.00 ≤1.0 ≤0.04 ≤0.03 17-19 ≤0.5 N≤0.04

904L ≤0.03 ≤1.00 ≤2.0 ≤0.035 ≤0.03 18-20 23-25 3.0-4.0 Cu:4.0-5.0