A355 Sømløst legeringsstålrør

A335-rørene har et højt niveau af krom og molybdæn tilstedeværelse i det. Mens molybdæn øger den samlede styrke, modstand, elasticitet, hærdbarhed og overordnet kvalitet, Moly sikrer, at materialet er mere modstandsdygtigt over for blødgøring, begrænser væksten af korn og mindsker chancerne for skørt. Det er det enkelte additiv, der er ansvarlig for stigningen i høj temperaturbestandighed, og det forbedrer også korrosionsbestandigheden over for stål.

- Beskrivelse: __________

- Undersøgelse

ASTM A335 P9, P11, P22, P91 Pipe specifications

ASTM A335 is the seamless ferritic alloy steel pipe that used in high-temperature services and boiler industry. Common used Grade P5, P9, P11, P22, P91.

ASTM A335 pipe also named as ASME S/A335 Chrome-Moly pipe, it is a type of seamless pipe used in high temperature environments of 540 – 750 °C. It covers nominal wall and minimum wall thickness pipe that with alloy material. The pipe under this specification shall be suitable for bøjning, flanging, and all the other similar processing and formations. Although it shall be good for fusion welding. the material could also used to produce pipe fittings like elbow, tee, reducers and flanges.

Grade P5, P9, P11, P22 and P91 pipe refer pipe fittings material in ASTM A234 WP5, WP9 ,WP11, WP22 WP91, where flange material in ASTM A182 F5, F9, F11, osv. They have similar chemical composition and mechanical properties.

Our Supply Range for A335 Pipe

Standard and Grades: ASTM A335 Grade P5, P9, P11, P22, P91

Material types: Chrome alloy steel pipe

Manufacturing types: Seamless pipe by hot rolled eller kold trukket

Størrelser: 1/2” to 24”

Vægtykkelse: SCH 40, SCH STD, SCH 80, SCH XS, SCH 160

Længde: 6 Meter, 12 meters or customized.

ASTM A335 Pipe Features

A335-rørene har et højt niveau af krom og molybdæn tilstedeværelse i det. Mens molybdæn øger den samlede styrke, modstand, elasticitet, hærdbarhed og overordnet kvalitet, Moly sikrer, at materialet er mere modstandsdygtigt over for blødgøring, begrænser væksten af korn og mindsker chancerne for skørt. Det er det enkelte additiv, der er ansvarlig for stigningen i høj temperaturbestandighed, og det forbedrer også korrosionsbestandigheden over for stål.

Chromium – Key Chemical Element for A335 Pipe

Chromium is a key component that is used in the manufacture of stainless steel. If the chromium levels are above 12%, it can be classified as stainless steel. The oxidation resistance potential of chrome is irreplaceable even in elevated temperatures. The hardness, tensile and yield strength is better at standard temperatures. Due to the composition of the material, it is ideal to be used in power plants, Raffinaderier, petro-chemical plants and other oil field services when there is transportation under high temperatures and pressures involved.

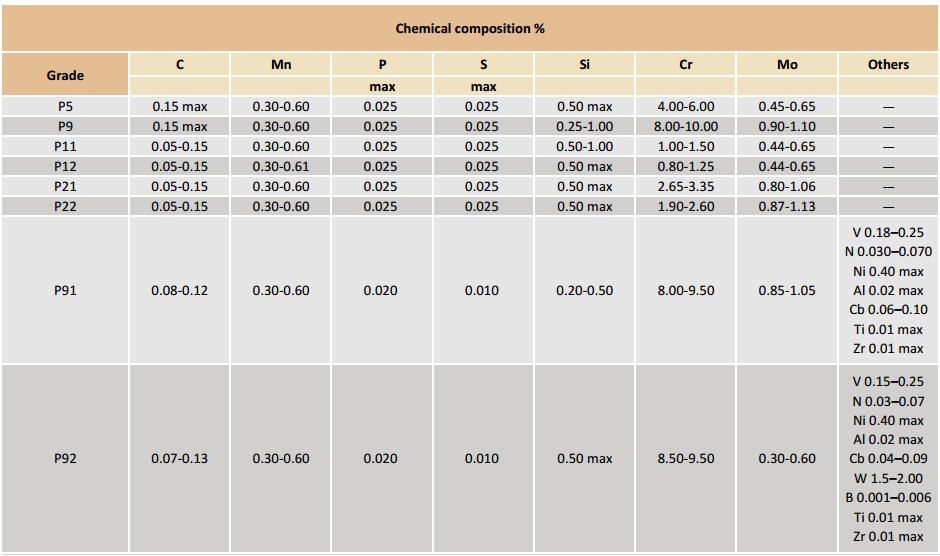

A335 Pipe Chemical Composition

Mekaniske egenskaber

|

Grad |

Yield Strength Mpa [ksi] |

Tensile Strength Mpa [ksi] |

Forlængelse % |

Hardness Brinell |

|---|---|---|---|---|

|

P5 |

205 [30] |

415 [60] |

30 |

207 .max |

|

P9 |

205 [30] |

415 [60] |

30 |

– |

|

P11 |

205 [30] |

415 [60] |

20 |

– |

|

P12 |

205 [30] |

415 [60] |

30 |

174 .max |

|

P22 |

205 [30] |

415 [60] |

30 |

– |

|

P91 (1,2) |

415 [60] |

585 [85] |

20 |

en |

en: P91 type 1 og 2 hardness range from 190 til 250 [HBW] eller 196 til 265 [HV] eller 91 HRBW to 25 HRC.

Dimension Tolerances

Tolerance in wall thickness:

|

NPS [DN] Designator |

Tolerance % on Wall Thickness |

|

|---|---|---|

|

Over (+) |

Under (-) |

|

|

1/8 til 2 1/2 [6 til 65] for all t/D ratios |

20.0 |

12.5 |

|

Above 2 1/2” [65], t/D ≤ 5% |

22.5 |

12.5 |

|

Above 2 1/2 [65], t/D > 5% |

15.0 |

12.5 |

|

t = Wall Thickness; D = Outer Diameter |

||

Permissible variations for Outer Diameter:

|

NPS [DN] Designator |

Over (+) |

Under (-) |

||

|---|---|---|---|---|

|

in. |

Mm |

in. |

Mm |

|

|

1/8 til 1 1/2 [6 til 40] |

1/16 (0.015) |

0.40 |

1/16 (0.015) |

0.40 |

|

Over 1 1/2 til 4 [40 til 100] |

1/32 (0.031) |

0.79 |

1/32 (0.031) |

0.79 |

|

Over 4 til 8 [100 til 200] |

1/16 (0.062) |

1.59 |

1/32 (0.031) |

0.79 |

|

Over 8 til 12 [200 til 300] |

3/32 (0.093) |

2.38 |

1/32 (0.031) |

0.79 |

|

Over 12 [300] |

+/- 1% of the specified outside diameter |

|||

P91 pipe – A Premium Alloy Pipe

ASTM A335 Grade P91 pipe is premium grade pipe applied for high pressure boiler. And P91 pipe is ideal when it comes to bending, flanging or when it is used in similar operations such as welding. The material of steel should stick to the composition of chemicals, tensile property and the requirements of hardness.

ASTM A335 P91 alloy steel pipe and high pressure boiler pipes are the two variants available and the range is dependent based on the size, which is solely based on the usage. The length of the pipe will be subject to hydrostatic test and there will also be a non-destructive examination based on the specifications.

Som følge heraf, The chrome moly pipe finds high usage in power generation industry and petrochemical industry owing to its resistance to corrosion, Trækstyrke, strength for high temperature owing to its cost-effectiveness.

P5, P9, P11, P22, P91 Pipe Application

This chrome moly pipe featured grades are ASTM A335 P5, P9, P11, P22, P91, so also it could be called as P Grade pipe in some cases.

P11 pipe, P22 pipe and P91 pipes are used in power industry and petro-chemical plants, meanwhile, P5 and P9 pipe generally find usage in refineries.

Ordering Information

To purchase ASTM A335 pipe should include the following, as required, to describe the desired material adequately:

en. Quantity (fødder, metres, or number of lengths),

b. Name of material (seamless alloy steel pipe),

c. Grad (Table 1)

d. Manufacture (hot-fifinished or cold-drawn),

e. Size useing in NPS & Schedule number, or OD (ID) and Wall thickness (minimum/nominal)

f. Længde (specifific or random),

g. End fifinish (Ends Section of Specifification A999/A999M),

h. Optional requirements (Hydrostatic Test Required or not and Permissible tolerance in weight.)

i. Specifification designation, and Special requirements or any supplementary requirements selected, or both.